Totally Porous vs. Superficially Porous HPLC columns

The Problem: The Pressure vs. Efficiency Trade-off

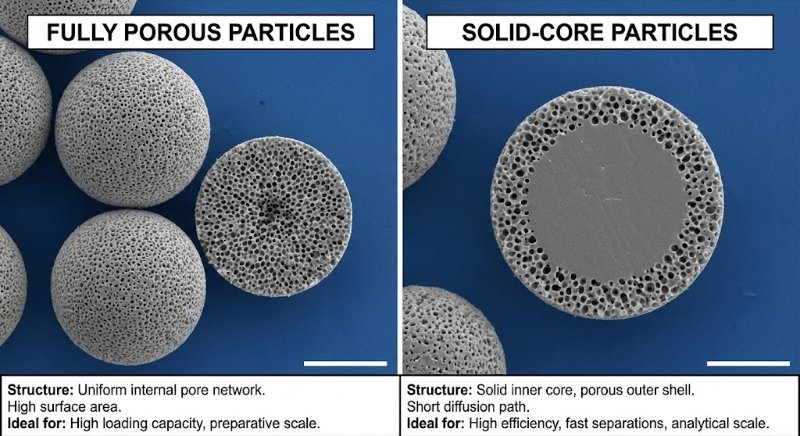

Totally Porous Particles (The Old Standard): These are like "sponges" or "Nerf balls"—pores go all the way through. To get better separation (efficiency), you need smaller particles.

The Trap: As you shrink the particle size (e.g., from 3.5 µm to 1.8 µm) to sharpen peaks, the backpressure skyrockets (often quadruples). Standard HPLC instruments (max ~6000 PSI) cannot handle the pressure required by these sub-2 micron particles.

The Solution: Superficially Porous Particles (SPP)

Also known as Core-Shell or Porous-Shell particles, these offer a "best of both worlds" solution:

The Structure: They have a solid, non-porous core (like a glass marble) coated with a thin porous shell.

Example: A 1.7 µm solid core + a 0.5 µm porous shell = 2.7 µm total particle size.

Why It Works:

Lower Pressure: The pump "sees" a larger 2.7 µm particle, keeping backpressure low enough for standard HPLC instruments.

Higher Efficiency: The sample molecules only have to diffuse through the thin outer shell (short diffusion path). This mimics the physics of a much smaller (~1 µm) particle.

Key Takeaway

Superficially porous columns allow you to achieve UPLC-level efficiency (sharp peaks) using standard HPLC hardware (lower pressure).